What is extrusion in 3D printing?

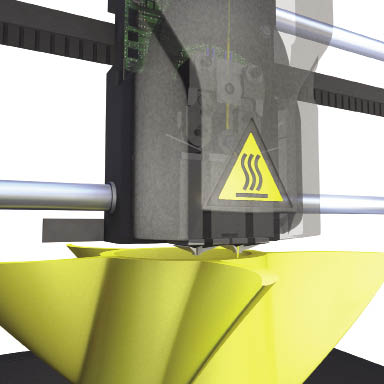

According to the ASTM International standards organization, extrusion is the official name given to a specific 3D printing process where material is selectively dispensed through a nozzle or orifice. Extrusion is more commonly known as Fused Deposition Modeling (FDM)®, a registered trademark by Stratasys Ltd, or Fused Filament Fabrication (FFF), a non-trademarked term.

Extrusion is the most common and probably the simplest 3D printing technique. It can be used in almost every environment. The main printing material is a plastic filament. The filament is heated, melting in the printing head of the 3D printer.

Extrusion is an “additive” technology commonly used for modeling, prototyping, and production applications. It creates an object by laying down material in layers; a plastic filament or metal wire is unwound from a coil and supplies material to produce a part. The technology was developed by S. Scott Crump in the late 1980s and was commercialized in 1990.

‘Extrusion’ was a term I had heard thrown around when people talked about 3-D printing, but I never really know what it meant until I read this article! Thank you for sharing.

Wow very nice post and very informative article i just buy my 3d printers to this website and they have best 3d printers for sale!

A well informed post you provided for 3D printer community as likely new users try to understand the 3D printer and these types of post are the most uefull in learning.

Worth reading! Thanks for a pretty awesome explanation about extrusion in 3D printing. I am living in and for all my Custom Plastic Extrusions needs in Michigan, I prefer to contact my local contactor only. Looking to see some more informative posts from your end in the future. Thanks!!

I got a laugh at “duel” extruder. I visualized two extruders contending for the same spot.

I suspect the word you meant was “dual,” meaning two.

Otherwise a very informative post. Thanks