Julliette Combe is a mechanical engineer. She began working on 3D printing during her master thesis on nano 3D printing. When she joined Formlabs, she first went into the business development team for product partnership and worked on custom products … [Read more...] about 3D printing makes it easy to develop tooling for production

Rapid Injection Molding

Micro molding – The need for collaboration and DfM

There are a certain set of rules and understandings of the molding process at the macro level that simply don’t work at the micro level. The flow of molten plastic, it's cooling, warpage, necessary venting and gating … are all different when molding … [Read more...] about Micro molding – The need for collaboration and DfM

Advances in vertical injection molding make medical device design easier

By John Schmitz, President of Aberdeen Technologies, Inc. The medical sector has embraced the high standards that plastic injection molding can offer. Insert molding, especially on a vertical molding press, can hold tight tolerances while also … [Read more...] about Advances in vertical injection molding make medical device design easier

Tips on working with gates in micro-molded parts

By Scott Byal, Sr. Project Engineer, Accumold As technology shrinks, previously overlooked aspects of injection molded parts are causing significant challenges and problems. With larger injection molded parts, the gate, where polymer enters the … [Read more...] about Tips on working with gates in micro-molded parts

Custom color and complete parts made easy

Color can play an important role in product design. Achieving the right color, however, has usually been a challenge. It can take weeks to get the color right. Noted Joel Matthews, Global Product Manager – Secondary Operations at Protolabs, a typical … [Read more...] about Custom color and complete parts made easy

Injection molding helps inventors meet accelerated timeline

A Minneapolis-based startup has developed a “personal malt-house” for those who enjoy home brewing beer. This personal malt-house, the Acro, is from Sprowt Labs. Home and craft brewers have not had a large assortment of home breweries to choose … [Read more...] about Injection molding helps inventors meet accelerated timeline

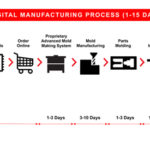

The difference between traditional and rapid molding

The “digitization” of nearly every process to make products continues. The latest industry to experience this shift is molding. Here’s a look at how digitization may affect traditional molding service providers. Pierre Viaud-Murat | Senior Vice … [Read more...] about The difference between traditional and rapid molding

A guide to using thermoforming, injection molding, or reaction injection molding

When it comes to plastic parts, is thermoforming, injection molding or reaction injection molding better? Each of these methods of plastics manufacturing has its benefits; and the ideal one for a given product depends on a number of factors, … [Read more...] about A guide to using thermoforming, injection molding, or reaction injection molding

How a music tech startup conquered the production challenge

Driven by a successful Kickstarter campaign, Boulder, Colorado-based, connected-musical applications company Specdrums had a challenge on its hands. With orders in the queue, the growing company needed production help – they needed it fast, and in a … [Read more...] about How a music tech startup conquered the production challenge

How to build a robotic exoskeleton with digital manufacturing

When Parker Hannifin CEO Don Washkewicz challenged his team to explore the future of the company seven years ago, the team explored robotic devices, such as a robotic exoskeleton, for medical applications. Parker has key core competencies in motion … [Read more...] about How to build a robotic exoskeleton with digital manufacturing