10. Internal stress

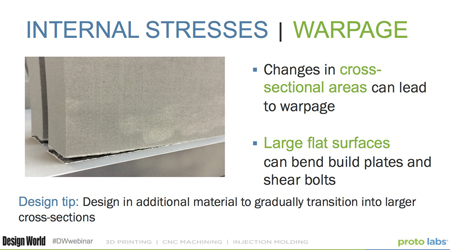

Internal stresses form from rapid heating and cooling. The previous bridge part was a good example of movement that can happen during the sharp changes in cross-sectional area. Outer legs were vertical but they were pulled in due to the force of the large flat surface. Flipping the geometry can prevent this, but that may not always be possible. Gradual archways between posts can help reduce or prevent internal stresses.

A large solid part can bend build plates and shear bolts, known as warpage. This is not always caused by a bad built start position, which can happen and lead to weak adhesion. In this case, the part actually tore pieces out of the 1-in. thick titanium platform; large parts can warp a 1-in. thick plate by as much as 0.05 in. A design tip is to design additional material and gradually shift into larger cross sections to help reduce that internal stress.

For more design tips, contact Proto Labs.

Thanks for making such a cool post which is really very well written.

Wow! Wonderful. Great Great Great Post. Thank You LESLIE LANGNAU .Thank you very much