5. Internal features

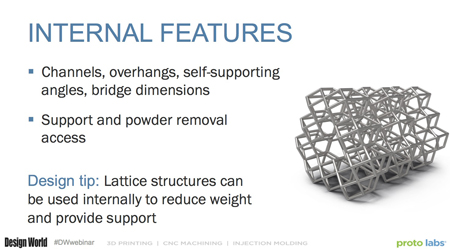

Additive manufacturing is unique in that you can create internal features within a single part file, but this must be done cautiously. Be sure to consider channel size and shape, overhang distances, self-supporting angles, and bridge dimensions.

Supports may be needed on internal features. These may not be removable, which can interfere with function. There should also be some way for powder to be removed after the build process is complete. Trapped internal powder is a common occurrence seen by additive service providers. A design will have an open cavity that will collect powder but no means of removal once the build is complete. Consider replacing the voids with a self-supporting lattice structure. First, such a structure greatly reduces the weight of the part and will build with less internal stress.

Thanks for making such a cool post which is really very well written.

Wow! Wonderful. Great Great Great Post. Thank You LESLIE LANGNAU .Thank you very much