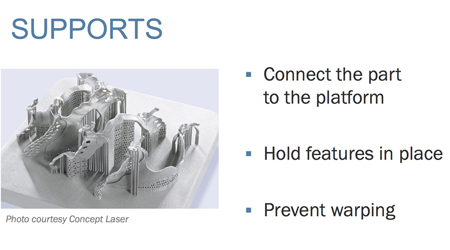

4. Supports

In DMLS, supports exist for two main reasons. First, they hold the parts in place during the build process. Every build starts out with a blank build plate and the parts need to be connected to the plate. The supports put some distance between the part and the plates for easy part removal.

The second reason for supports is to prevent the part from warping from the intense internal stresses created during the build process. Because each layer is rapidly melted and cooled, internal stresses build up as a part is built. If you built a thin flat plate without supports, it would basically curl up like a chip.

When parts have thick cross sections, the amount of supports required to prevent warping increases, in turn creating more work during support removal as well as creating more laser time, which inherently increases the cost of the part.

Support removal can add costs. Removal options include CNC or manual machining, lathing and EDM, which can add time and cost but can create for a better part in the end. Some of these secondary operations also reduce the internal stresses from the build.

A lot of support removal can be manual, which can affect part dimensions. A good design tip is to design parts so that they require minimal supports, for example, by creating self-supporting features.

Thanks for making such a cool post which is really very well written.

Wow! Wonderful. Great Great Great Post. Thank You LESLIE LANGNAU .Thank you very much